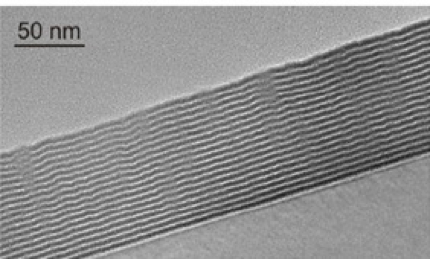

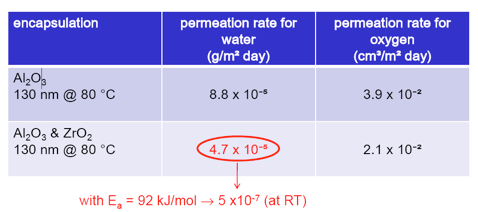

Reliable, high-performance encapsulation is becoming increasingly critical as semiconductor devices continue to grow more complex and sensitive. Encapsulation serves as a barrier that protects delicate device structures from environmental contaminants such as moisture, oxygen, and particulates that can degrade performance or shorten product life. Al2O3 / ZrO2 nano laminate film for OLEDs Ref: Meyer, J. et al. Appl Phys Lett 94, 233305 (2009).

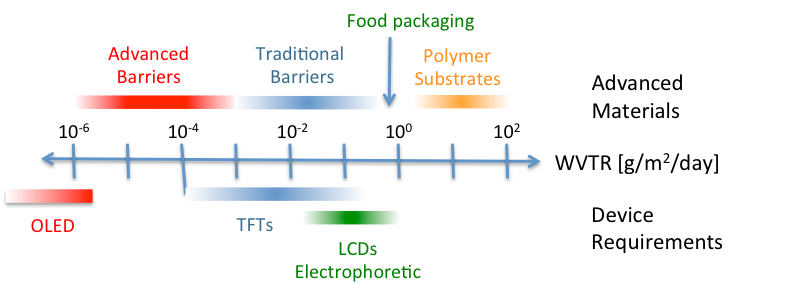

Encapsulation and barrier layers are one of the most striking success stories of ALD and are now used in production to fulfill stringent applications such as OLED or flexible electronics. ALD can deliver uniquely dense pinhole-free films making it the technique of choice to obtain high-quality ultra-thin moisture barrier layers and anti-oxidation films. The ability to deposit nanolaminate films with atomic-level thickness control enables to achieve excellent permeation performances with water transmission rates below 1E-6 g/m2/ day while ALD superior conformallity will provide full coverage even over complex 3D nano- and micro-structures, making it highly suitable for MEMS / NEMS applications. The film properties can also be tuned to ensure that it remains optically transparent and clear to the eye making it attractive to protectively coat precious metals and artifacts.

THIN FILM ENCAPSULATION

91��Ƭ��Cambridge Nanotech has been at the forefront of the development of ALD films for encapsulation and barrier layers. Pioneering works from Carcia and Meyer on Savannah® ALD platforms have demonstrated the potential of ALD to fulfill the most stringent encapsulation requirement with water transmission rates below 1E-6g/m2/day. Our scientists have years of experience in the development of hybrid organic / inorganic films deposited by MLD (Molecular Layer Deposition) integrating organic layers such as alucone or zircone in an inorganic oxide matrix. Such hybrid materials can provide more flexible films while still ensuring superior impermeability.

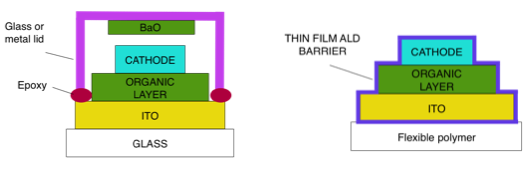

The low thermal budget and ultra thin nature of these films has proved critical for the most stringent applications such as OLEDs or flexible electronics applications on organic substrates such as PEN or PET.

Encapsulation by ALD can also provide excellent oxidation barrier on metals and has been successfully used to protect coins, artifacts and other oxidation-sensitive materials.

ALD Benefits for Encapsulation

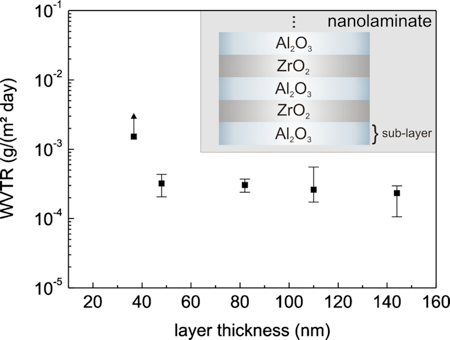

ALD thin films can provide optimal moisture barriers films to satisfy the most stringent applications such as OLEDs with water vapor transmission rate below 1E-6 g/m2/day for films thinner than 50 nm.

Ref: Advanced Materials 2009, 21, 1845-1849

Advanced thin films barriers are required for MEMS and OLED packaging. ALD can deliver ultra-thin encapsulation with superior conformallity and thickness control making it the technique of choice for flexible electronics.

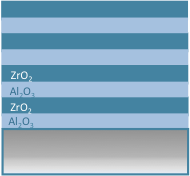

ALD enables to deposit multi-component nanolaminate oxides to combine Al2O3 excellent moisture barrier performance with the anti-corrosion properties of alternative oxides such as HfO2, ZrO2 or SiO2 in aqueous environments.

Nanolaminate oxide deposited at 80˚C in Savannah® as an encapsulation for low cost OLEDs.

Impact of layer thickness on Water Vapor Transmission Rate (WVTR). WVTR at 3.2E-4 g/m2/day at 80˚C for 40 nm film corresponds to 8.7E-7 g/m2/day at room temperature.

Ref: Meyer, J., et al. Applied Physics Letters, 96, 243308 (2010).

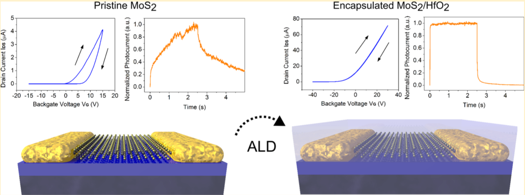

Encapsulation by ALD can be employed in a broad range of applications. In the above example, HfO2 is used to protect a 2D MoS2-based sensor from the environment while maintaining the device record responsivity and sensitivity.

Ref: Kufer, D. & Konstantatos, G.. Nano Lett 15, 7307–7313 (2015).

ALD is ideal to provide cost-effective anti-tarnish coatings on precious metals and artifacts. This technique can be readily scaled up to meet your production requirement in a cost effective solution.

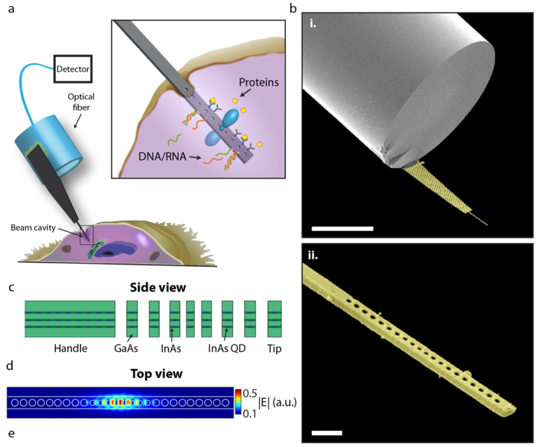

A 7-10 nm Al2O3/ ZrO2 nanolaminate is deposited on a GaAs photoluminescent nanocavity probe. The device is used to probe a single cell and the ALD nanolaminate prevents the photo-induced oxidation in the aqueous media without altering the device response.

Shambat, G. et al. Single-cell Photonic Nanocavity Probes. Nano Lett 130206113907001 (2013)

View publication review on Encapsulation Films done in 91��Ƭ��CNT platforms