ALD for highly controllable thin films

- Film thickness based on self-limiting, self assembled behavior, with nanometer level control

- Stoichiometric control of multicomponent films

- Films/Processes scalable over very large areas

- Excellent repeatability

- Wide process windows (with respect to temperature or precursor dose variations)

- Low defect density

- Amorphous or crystalline film types depending on substrate and temperature

- Fine control of multilayer coatings, heterostructures, nanolaminates, mixed oxides, graded index layers, and doping

- Standard recipes available for oxides, nitrides, metals, and semiconductors

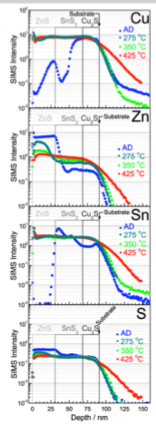

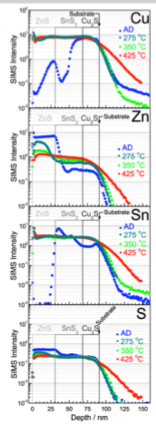

Cu2S/SnS2/ZnS trilayer deposited in silicon trench. CZST film composition profile is analyzed by SIMS following different thermal anneals.

Ref: Thimsen et al, Chemistry of Materials, 24 (16), 3188-3196 (2013). doi:10.1021/cm3015463

ALD for highly controllable thin films

- Excellent conformality, 100% step coverage: uniform coatings on flat, inside porous, and around particle samples

- Atomically flat and smooth coating that conforms to the substrate geometry

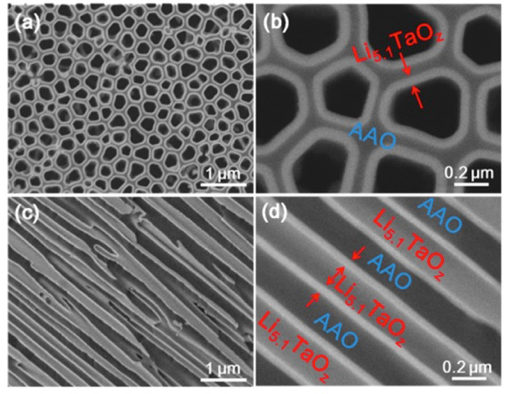

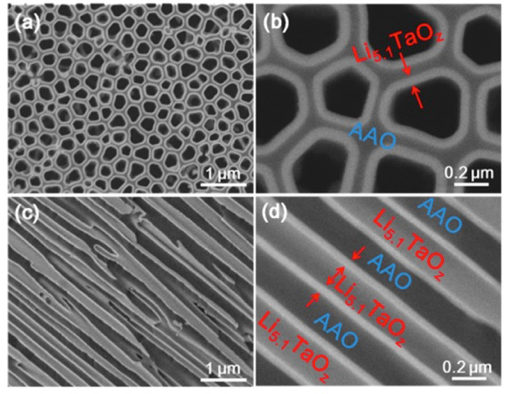

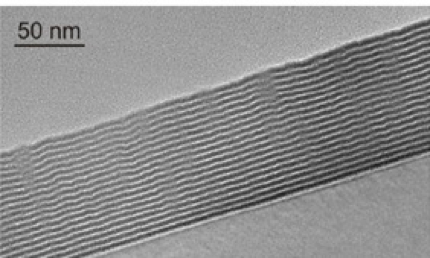

Conformal deposition of Li5.1TaOz deposited by ALD in 300:1 AAO nanotemplate (470:1 final AR)

Ref: Liu, J. et al., J. Phys. Chem. C 117, 20260–20267 (2013).

ALD for challenging substrate

- Gentle deposition process for sensitive substrates

- Low temperature deposition possible (RT-800 °C)

- Low power plasma processing (as low as 20-50W) capability

- Coatings demonstrated on polymers, OLEDs, and noble metal surfaces

- Excellent adhesion due to chemical bonds at the first layer

- Low stress due to molecular self-assembly

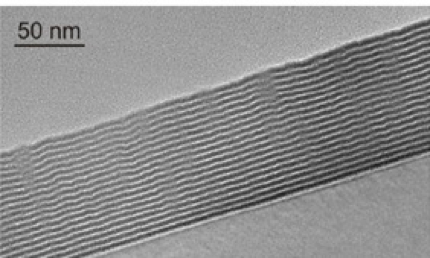

Al2O3 – ZrO2 nanolaminate encapsulation with a water transmission rate (WVTR) of 5E-7g/m2/day at room temperature – deposited in Savannah® at 80˚C

Ref: Meyer, J., et al. (2009). Applied Physics Letters, 94(23), 233305